Single Inboard

Check out our shop to learn more about each product in the system.

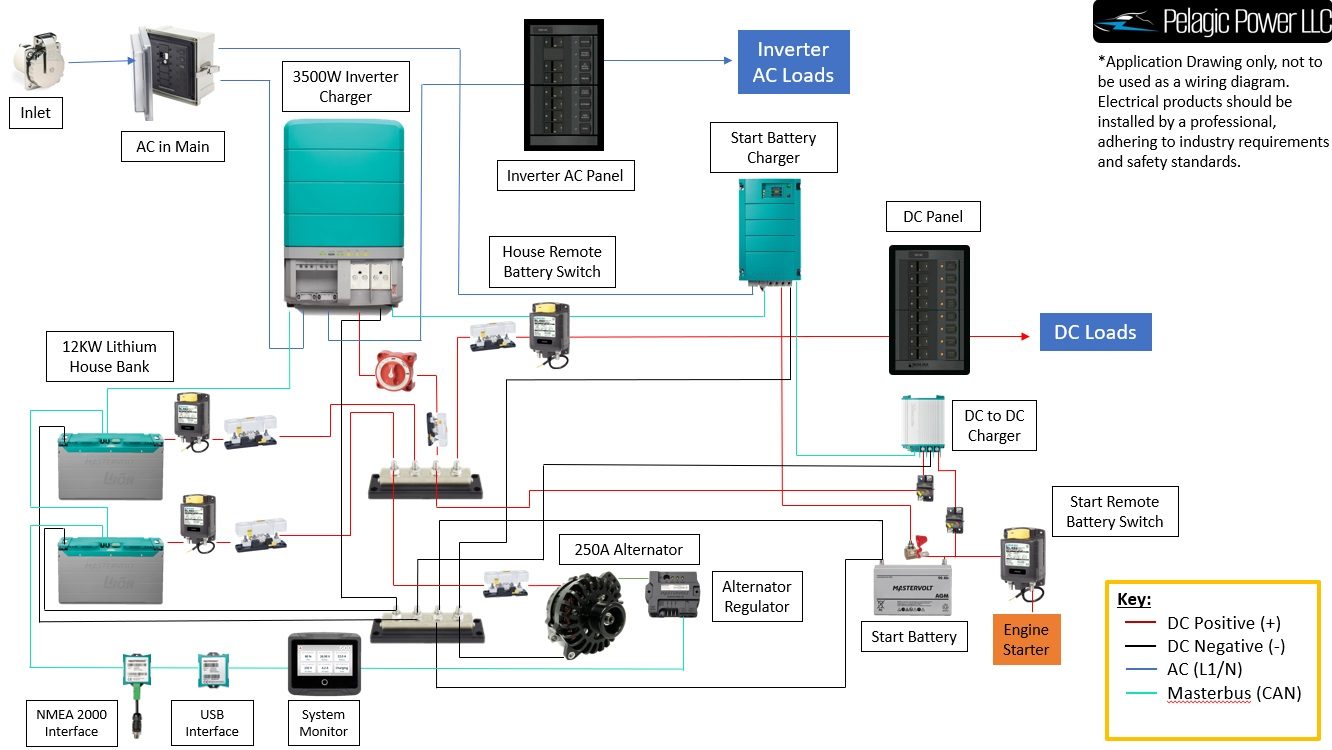

System Overview

Single engine inboard boats or vehicles with 120V AC

This system is specifically called out as inboard because it involves upgrading an alternator to directly charge a lithium battery bank.

Specifications:

System was designed at 12V but specification numbers would change very little at 24V

- 10.8KW Hours of Lithium house batteries (90% depth of discharge)

- 12KW Hours @ 100% depth of discharge (not recommended)

- 3500W AC power from the Inverter/Charger

- 50A @ 120V AC shore power/AC auto transfer

- This system will also work on 30A as well

- 200A house battery charging from the Inverter/Charger

- 250A house battery charging directly from the engine alternator

- 50A of start battery charging while from alternator through DC to DC charger

- 25A of start battery charging from dedicated battery charger

How It Works:

In a single engine boat most customers want as much power out of the alternator as possible since it’s the primary charging source when away from the dock. To maximize that power the system requires upgrading alternators to an ElectroMaax 250A GenMaax with remote rectifier. You can read more about that alternator on our product page found here.

With up to 250A of power generation available you will need somewhere to store all that power. That is where a pair of 6000W Mastervolt MLI Ultra batteries comes in. These batteries are the house bank and are directly connected to the alternator output. The beauty of this system is when using the GenMaax you can pair it with the Mastervolt Alpha Pro 3 external regulator. This allows the alternator to communicate directly with the MLI Ultra batteries. If the batteries ever want to stop charging they can automatically communicate that with the regulator and shut current off from the alternator with no risk of damage or back feeding. We feel battery to alternator communication is required when direct charging lithium from an alternator.

One call out is the Alpha Pro 3 regulator only operates on N-Type alternators. Most alternators in North America are P-Type. So if you want to go down this path we just need to special order an N-type version for you. The good news is all ElectroMaax alternators we sell can be special ordered as N-type.

Since the house bank is being directly charged by the only alternator on the boat you will need a way to charge the start battery while under way. We recommend using lead acid start batteries for multiple reasons (outlined below). Since the system has mixed battery chemistries it is a perfect application for a DC to DC converter. We would utilize the Mac Plus line of DC to DC converters and program it to charge the start battery when the engine is running. Since the Mac Plus is also on the Masterbus network you can trigger the converter to turn on only when the regulator is active, which means the alternator is running. Then when the engine is off the converter will go into standby.

The beauty of the Mac Plus is if you wanted to trigger the charging off of voltage, or even an analog signal (like a rocker switch) you could. As you can see there are multiple ways to set up when you charge the start battery while under way.

With up to 12KW of lithium house battery being charged from a GenMaax alternator this system is begging for a large inverter. As designed, we propose a single 3500W 12V inverter-charger at 120V. The system could move up to 4500W if it was 24V or you could start paralleling inverters if you want more power or need to power 240V loads. Either choice, the 3500W inverter can handle 50A AC incoming and results in up to 200A of DC charging into the house bank at the dock. If you install this system with a 30A shore power service we recommend de-rating the inverter charge down to around 22A AC to allow for the start battery charger to pull 4A AC off of shore power. This de-rating is purely to prevent tripping shore power pedestal breakers while you are away from the dock.

Since there are now two battery chemistries onboard there will need to be a way to charge the lead acid start battery while on shore power. There are 2 different ways to approach this. In the diagram we recommend a small 25A battery charger for the start battery, which should never get very low since they are isolated from the house loads. This allows the system to run a dedicated battery charger for lithium and lead acid while shorepower is present. The system could also be designed where you run the DC to DC charger continuously and omit the start battery AC charger. When the larger inverter charger is charging the lithium house bank the DC to DC charger would take up to 50A and charge the start batteries. If AC shorepower is limited, this is a great option and further outlines the flexibility of the DC to DC charger. The choice is yours.

The system includes the ABYC recommended ELCI (Electrical Leakage Circuit Interrupter) that acts dual purpose as an AC main breaker and leakage detector. Wiring of AC is intentionally designed simply where all shore power goes through the ELCI to feed only 2 AC main loads, House Inverter Charger and Start Battery Charger. The Inverter can handle full pass through to all AC loads on the boat so the inverter acts as the feed to the AC panel. Therefore, the inverter is either in passthrough mode, or inverter. In systems with generators or large AC loads the inverter AC panel may be a sub panel of a larger AC panel.

The system is designed with a remote battery switch for the house bank and the start battery (2 total). The wiring allows you to turn off these switches when away from the boat and turn them off when ready to use so you don't have to turn off select breakers every time you leave the boat. You can see 2 other remote battery switches near the lithium house batteries and wonder why you need more battery switches. Those switches are part of a specialized relay bracket that sits on top of the lithium batteries joined to a Class T fuse block. Ready more about the relay brackets here. This is not a battery switch but wired directly to the battery management system of the batteries. if the batteries have a problem they will communicate to the relay and self-shut down. For that reason you still need a full house bank battery switch per ABYC. The last battery switch in the drawing is a manual switch for the inverter/charger. This could also be a remote switch but to keep costs down we recommend a manual. The reason being is this switch will almost never be turned off and is there for service work or in the event of an emergency when you need to shut power off to the inverter.

All Mastervolt products in this system are connected via ethernet (CAT 5e, RJ45) and communicate on Masterbus. Critical parameters will be displayed on the Easy View 5 monitor, and many functions can be controlled from the monitor. This monitor acts as a State of Charge DC monitor since the batteries have built in shunts, which is why you don't see any monitors in the DC panel. Also included is a Masterbus to NMEA 2000 interface box that allows critical metrics to be communicated onto your NMEA 2000 compatible MFD and from NMEA 2000 back to Masterbus. Lastly, you will see a USB interface box. This is a critical product that allows you to program the Mastervolt system to your specific needs.

In most systems we recommend lead acid batteries for starting engines, regardless of engine size.

Why Lead Acid Start Batteries?

1. Batteries will never go "offline" like a lithium batteries

2. High cranking amps for all engine sizes

3. Cost effective

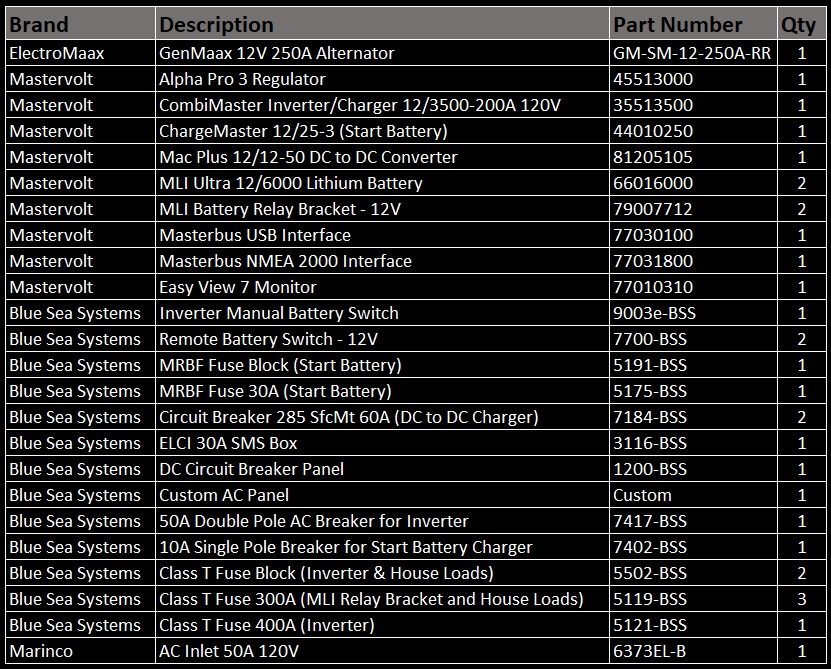

Bill of Materials*

*Contains only major components in the application diagram, does not have all required circuit protection devices, wiring, connectors, & bus bars

Ready to design your dream system?

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.